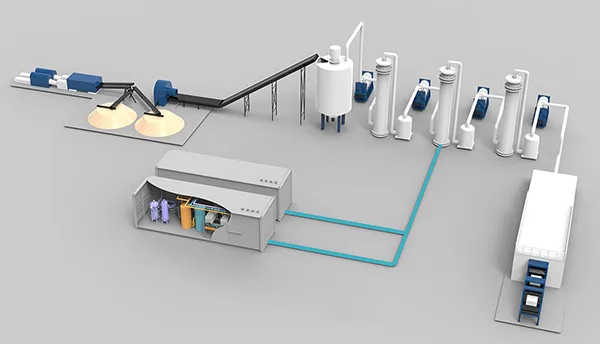

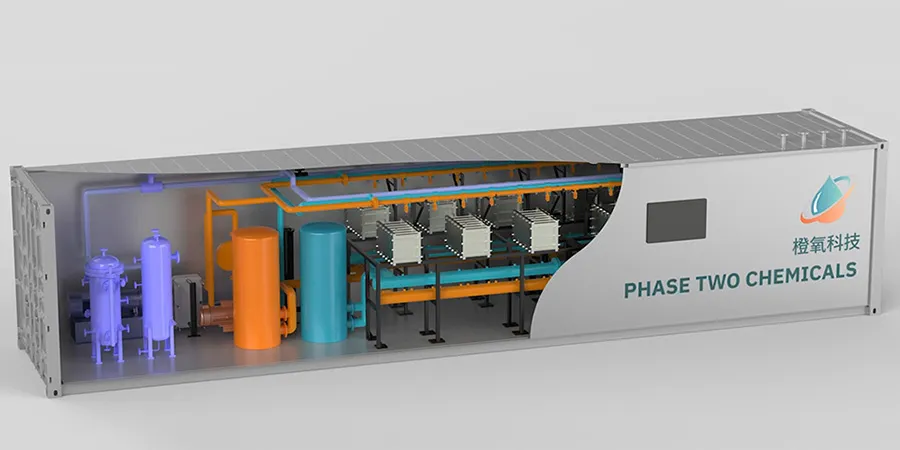

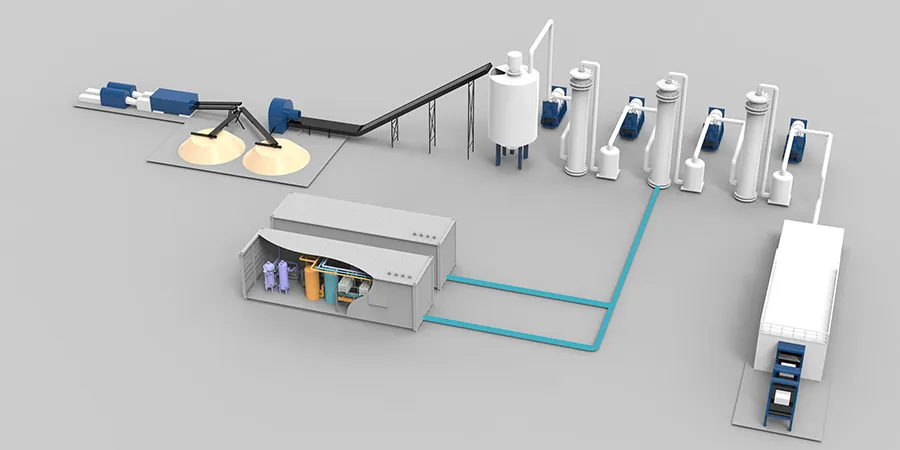

Alkaline hydrogen peroxide electrolytic generation system provides a more environmentally friendly, efficient, and safe choice for refiner mechanical pulping processes.

The process of producing pulp by processing wood through mechanical refining is known as mechanical pulping. This method does not use chemicals, resulting in lower processing costs and meeting environmental protection requirements. Moreover, using mechanical pulp can produce higher strength paper.

Since mechanical pulp does not use chemicals, the brightness of the produced paper products is not as high as those produced by chemical pulping processes. Therefore, this process requires a higher demand for bleaching agents. However, traditional bleaching agents are highly concentrated and explosive, leading to regulatory restrictions on transportation in many countries. Additionally, it requires the construction of a very safe high-concentration hydrogen peroxide storage system, and there may be shortages during peak hydrogen peroxide usage periods.

- Our electrolytic system only requires water, electricity, and oxygen to produce hydrogen peroxide, without pollutants, being more environmentally friendly with lower carbon emissions. Compared with traditional hydrogen peroxide production processes, our system can reduce carbon emissions by 2.492 tons per ton of hydrogen peroxide produced.

- The concentration of hydrogen peroxide produced by our system is controllable, with a maximum concentration of 6%, which is safe and controllable, and does not require additional storage systems.