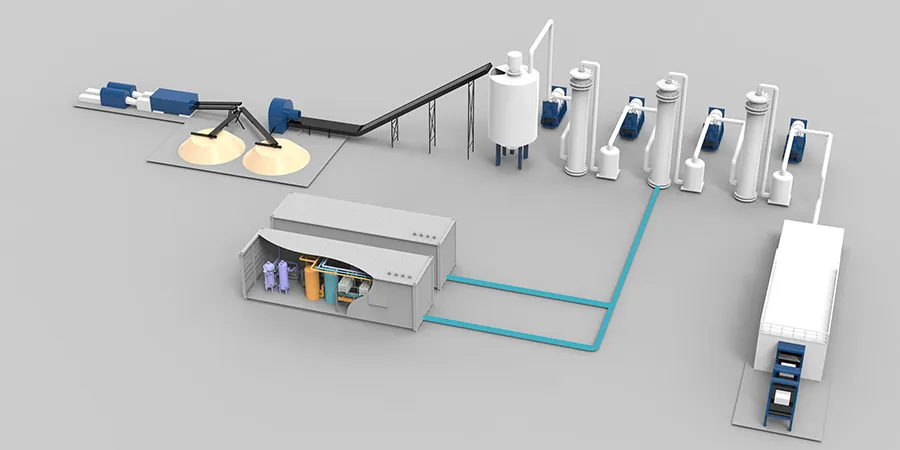

Paper and pulp manufacturing companies use low-concentration hydrogen peroxide to bleach pulp processed from cypress wood. This helps to retain the easy processing characteristics of cypress wood and preserve the quality of cypress wood cellulose, making it easier for papermaking companies to produce high-quality products.

- Softness: cypress wood features soft fibers, making it suitable for producing paper with a soft texture.

- Moderate fiber characteristics: The fibers are short, but have a soft texture, fine structure, and corrosion resistance.

- Special application potential: Due to their softness and fiber characteristics, cypress wood is suitable for the production of certain types of special-purpose papers.

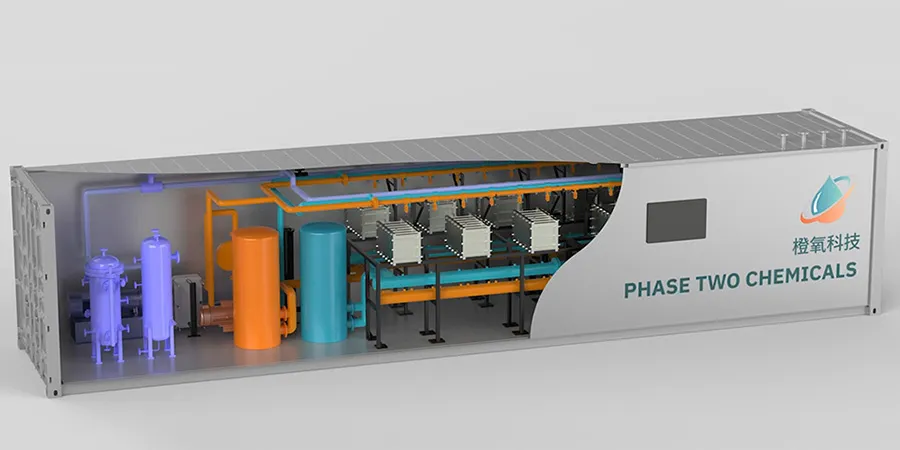

- By using our hydrogen peroxide production system, it can effectively reduce your operating costs by 20% to 40%.

- The electrolytic hydrogen peroxide production system ensures continuous supply without the need for additional storage systems, and the production volume of hydrogen peroxide can be adjusted according to demand.

- The electrolytic hydrogen peroxide generation equipment ensures more reliable production, eliminating the complexity and uncontrollable factors of traditional hydrogen peroxide production processes, as well as the risk of explosion.