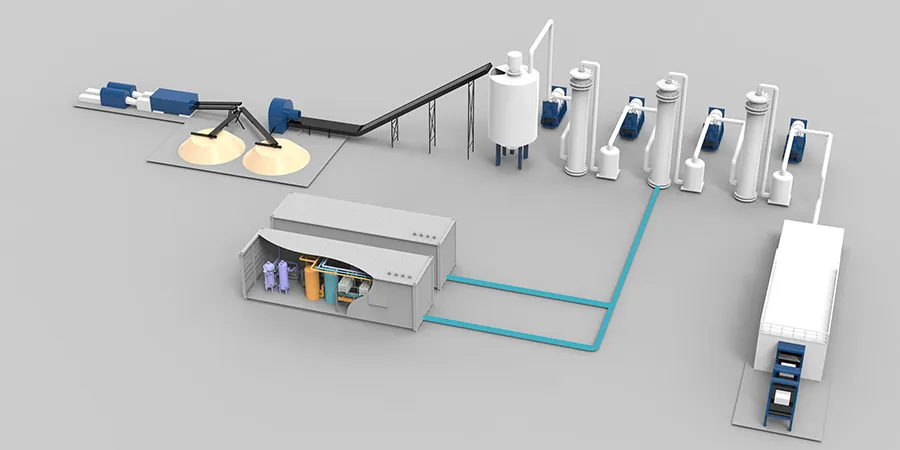

Eucalyptus, due to its low lignin content and easy diffusion, has been shown through structural tests to be easy to cook and bleach. Eucalyptus pulp requires minimal raw materials per ton, resulting in a highly cost-effective solution for the papermaking industry.

Applications of Eucalyptus Wood- Eucalyptus pulp is used to produce various types of paper, including high-quality writing paper and specialty paper, providing the papermaking industry with a choice of high-quality raw materials.

- Eucalyptus pulp is used in the production of textiles, such as rayon, known for its softness and strength.

- Eucalyptus pulp can be used as a source of bioenergy for power generation or as a fuel source.

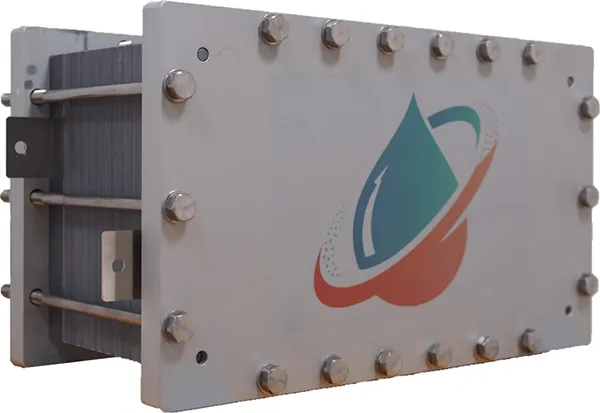

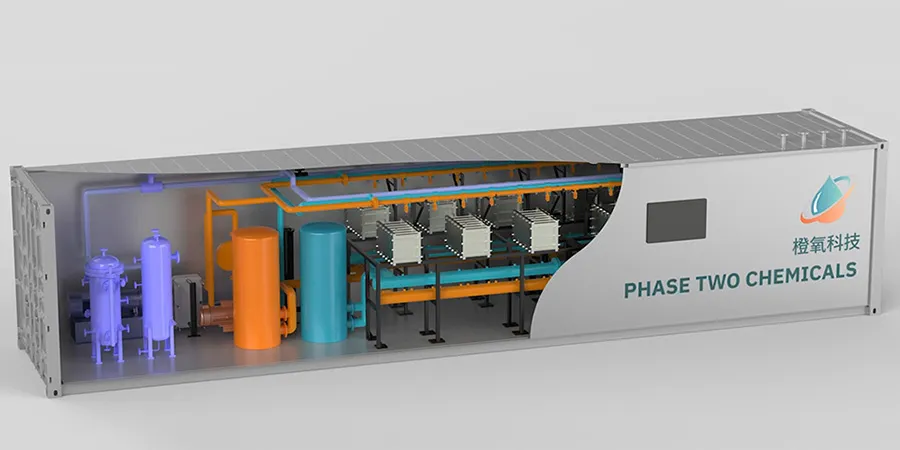

- We offer an intelligent integrated hydrogen peroxide generation system that solves space-related issues. Our equipment can be installed anywhere, making it highly convenient.

- Our hydrogen peroxide production system uses a self-developed electrolysis system, making the manufacturing process more controllable and easier to manage.

- Our alkali hydrogen peroxide system can continuously and stably produce low-concentration hydrogen peroxide using only electricity, oxygen, and hydrogen, effectively resolving transportation and storage issues while meeting the environmental protection requirements.

- The hydrogen peroxide produced by our electrolysis system features a concentration of no more than 6%, eliminating the risk of explosions associated with traditional processes.

- Low-concentration hydrogen peroxide effectively preserves the pulp characteristics of eucalyptus, making it easier to produce higher quality paper and textiles.

- We offer one-stop services for all your needs, from equipment assembly, user training, fault resolution, to equipment upgrades.