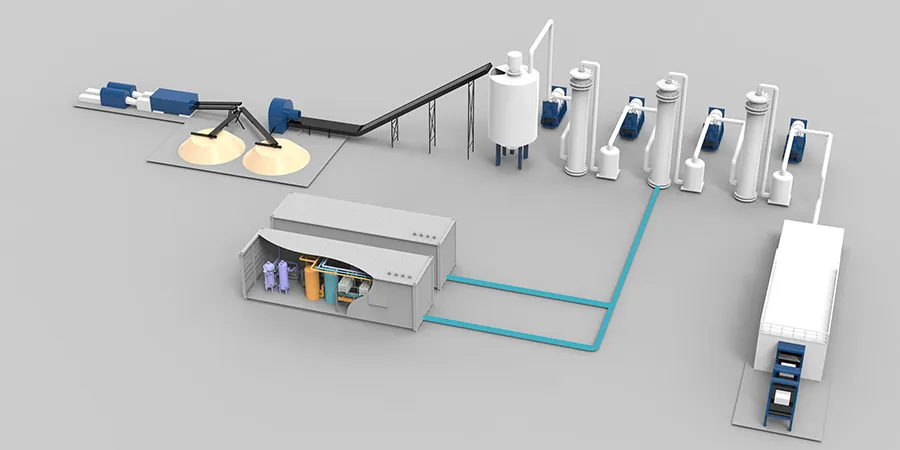

Located in a southwestern province of China, this factory produces 200,000 to 400,000 tons of chemical pulp annually, with a maximum daily hydrogen peroxide usage of about 7-10 tons (calculated at 100% concentration).

Due to the challenges associated with purchasing hydrogen peroxide externally - such as high-risk transportation of explosive high-concentration hydrogen peroxide, storage difficulties, supply uncertainty during holidays, and shortages during peak usage periods, the company has been searching for new bleach production solutions. They eventually discovered Phase Two Chemicals and established a cooperative relationship.

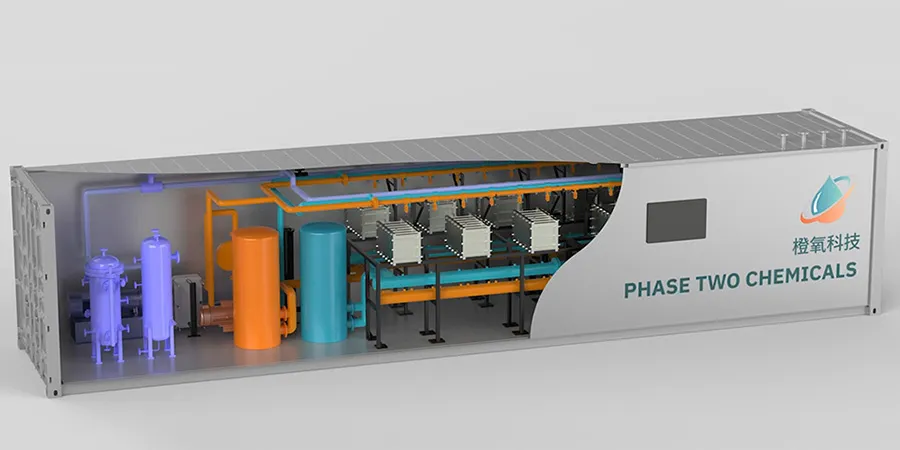

Phase Two Chemicals provided the group with an on-site hydrogen peroxide production project that was constructed in two phases and could completely replace externally purchased hydrogen peroxide once it was operational. The pilot project is currently in operation and has successfully demonstrated that alkaline hydrogen peroxide can be used as an effective substitute for the previously purchased hydrogen peroxide. Equipment stability and energy consumption meet required key technical indicators.