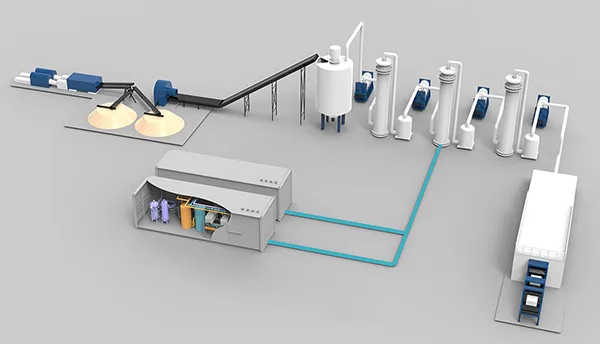

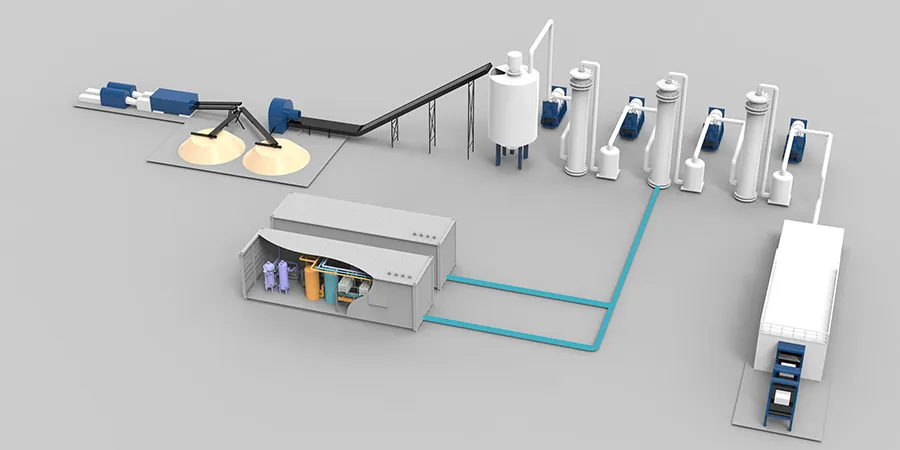

(P-RC APMP) Process

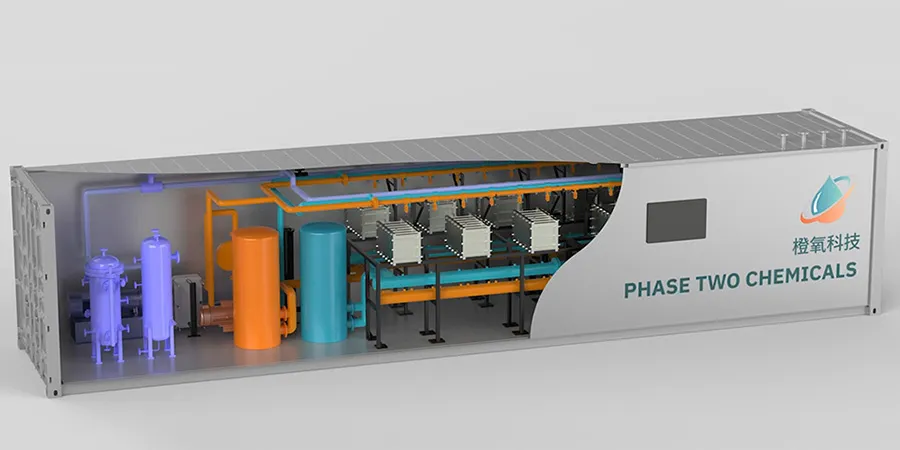

Alkaline hydrogen peroxide electrolytic generation system provides a more environmentally friendly, efficient, and safe choice for pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP) process.

P-RC APMP process is a highly flexible method of pulp production that combines chemical and mechanical pulping processes to improve the properties of pulp. The obtained pulp is similar to stone ground wood (SGW) pulp, but with higher strength and lower light scattering coefficient. And the pulp is similar to chemical pulp but has higher bulk thickness.

Advantages of P-RC APMP process:P-RC APMP pulp can partially replace chemical pulp, helping to reduce production costs. This method provides a flexible and efficient option for pulp production, meeting the needs of various paper products.

- Non-uniform bleaching: During the alkaline hydrogen peroxide bleaching process, uneven bleaching may occur, leading to unstable pulp quality.

- Issues with paper quality: Impact on paper strength: excessive use of hydrogen peroxide may damage the fibers, leading to reduced paper strength and durability. Impact on paper color: The bleaching process may affect the color stability of the paper, leading it to become yellow or gray.

- Environmental impact (wastewater treatment): Hydrogen peroxide bleaching generates a large amount of wastewater containing chemical residues, posing challenges for treatment.

- Chemicals cost: The cost of using bleaching agents like hydrogen peroxide is high, affecting the production economics.

- Our hydrogen peroxide generation equipment effectively solves the transportation and storage issues of bleaching agents and eliminates the potential risks.

- Our electrolytic generation system produces low-concentration hydrogen peroxide, effectively preserving the cellulose quality of various pulps, providing a reliable guarantee for paper mills to produce high-quality paper.

- The procurement costs for hydrogen peroxide can be reduced by 20% to 40%.