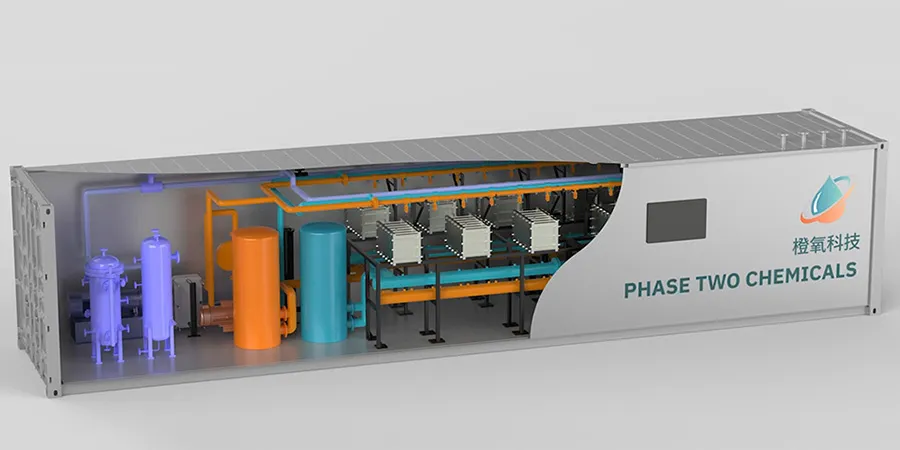

Our independently developed alkaline hydrogen peroxide electrolytic generation system provides a more environmentally friendly, efficient, and safe choice for deinking process.

Eliminating printing ink from recycled waste paper is an important measure for the sustainable development of the paper industry. Various methods using different principles are employed to effectively recycle and reuse the waste paper. Widely used chemical method involves the reaction between chemical agents and ink to decompose or dissolve the ink, thus achieving deinking of waste paper. Biological method is another effective approach that utilizes microorganisms to decompose the organic substances in recycled paper, achieving the purpose of deinking.

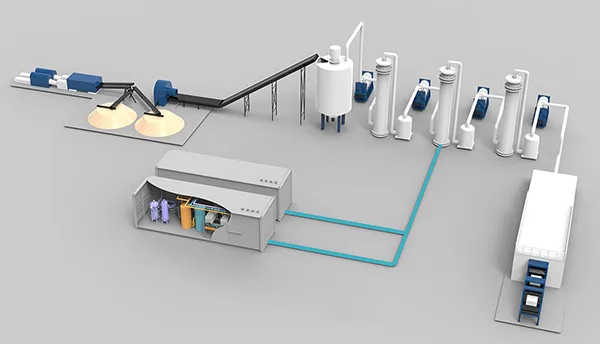

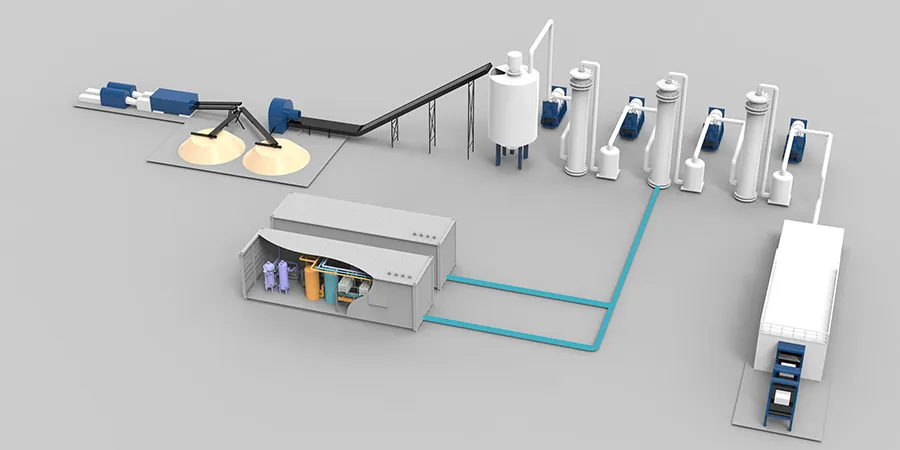

- Our hydrogen peroxide generation system produces low-concentration hydrogen peroxide, an environmentally friendly bleaching agent that effectively reduces environmental pollution. Hydrogen peroxide bleaching allows for controlled pulp color tune, enabling effective deinking of recycled paper.

- Our hydrogen peroxide production equipment only requires water, electricity, and oxygen for continuous and stable supply of low-concentration hydrogen peroxide, without the need for additional storage systems.

- The modular design of our electrolytic system allows for easy expansion of production capacity as needed.

- For deinking process, we provide a comprehensive leasing service, offering customers a one-stop bleaching solution with reduced investment, optimized production process, and peace of mind assurance.