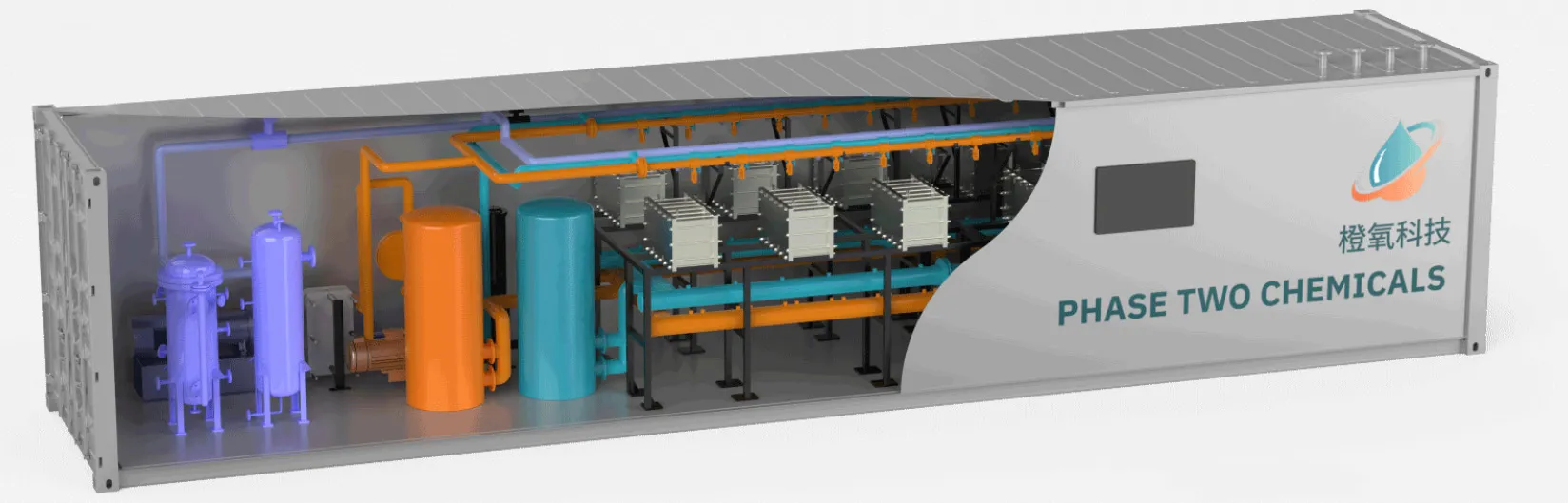

H₂O₂ Generation System

One-stop service, on-site assembly of hydrogen peroxide systems, installation, usage training, maintenance, and upgrade services

One-stop service, on-site assembly of hydrogen peroxide systems, installation, usage training, maintenance, and upgrade services

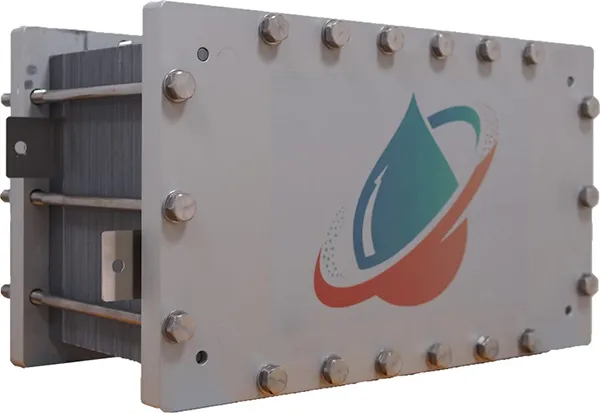

Alkaline hydrogen peroxide electrolytic generation system (model P1528) utilizes innovative technology to produce highly pure and stable alkaline hydrogen peroxide. Compared to traditional manufacturing systems, electrolysis is safer and more cost-effective, meeting the needs of hydrogen peroxide applications in pulp and paper bleaching and wastewater treatment fields.

Phase Two Chemicals provides services for end-users such as pulp and paper industry, waste paper recycling enterprises, as well as hydrogen peroxide manufacturers. This mode can reduce initial investment costs for customers and lower costs for partner companies by 20% to 40%. Additionally, we provide one-stop bleaching solutions to ensure stable and reliable equipment operation and safety.

Currently, our hydrogen peroxide generation system has been applied in pulp and paper enterprises, more industrial uses are being explored. Let us know if you are interested in using our system.

Using our alkaline hydrogen peroxide electrolytic generation system can bring the following four advantages for customers:

The hydrogen peroxide electrolytic production system is designed to produce hydrogen peroxide with a concentration below 5%, which is less prone to combustion and explosion, greatly improving the safety of the production process. Compared to traditional manufacturing systems, this electrolytic system reduces the transportation costs and difficulties in transporting high-concentration hydrogen peroxide, thus further enhancing the overall safety.

Our financial model effectively reduces initial investment and lowers the entry barrier for customers. The required raw materials for the innovative electrolytic generation system are simple and easy to obtain, and the production costs are effectively reduced. By avoiding the transportation of high-concentration hydrogen peroxide, transportation costs are significantly reduced as well.

The on-site production system only requires the supply of water, electricity, and oxygen to achieve continuous production, producing hydrogen peroxide as needed without the need for storage and eliminating the risk of supply interruption in traditional hydrogen peroxide supply caused by adverse weather, holidays, or supplier maintenance, etc.

We use electrolytic technology to produce hydrogen peroxide, effectively reducing carbon emissions. Compared to traditional hydrogen peroxide manufacturing processes, our production method can reduce carbon emissions by 2.492 tons per ton of hydrogen peroxide produced!

Compared to traditional metal-air batteries, Phase Two Chemicals has advanced metal-liquid-air batteries for grid-level long-duration energy storage. We can also design hydrogen peroxide electrolytic generation systems with different production capacities according to customers' hydrogen peroxide demand.

There is no need for complex environmental evaluations and approval procedures, as well as avoids the production of hazardous chemicals.

An annual pulp production capacity of 100,000 tons only requires a space of 200 square meters for the preparation of hydrogen peroxide, eliminating the need for large areas.

With the same production capacity, the investment of our equipment is less than that of traditional hydrogen peroxide anthraquinone generation equipment, reducing a significant amount of capital investment.

There is no need for supply of hydrogen gas, various organic consumables, and steam required in traditional hydrogen peroxide production technologies, which is beneficial for energy conservation and environmental protection.

The remote DCS control system enables more automation in operation, requiring only regular inspections and avoiding the high-cost manpower demands of operation and maintenance.

Our alkaline hydrogen peroxide electrolytic generation equipment operates under an equipment leasing model creates a predictable cost model for hydrogen peroxide.

Our experts can help you

Through our efforts, our hydrogen peroxide system produces hydrogen peroxide that can significantly reduce carbon emissions by 2.492 tons per ton. Our goal is to annually reduce carbon dioxide emissions from the global hydrogen peroxide industry by over