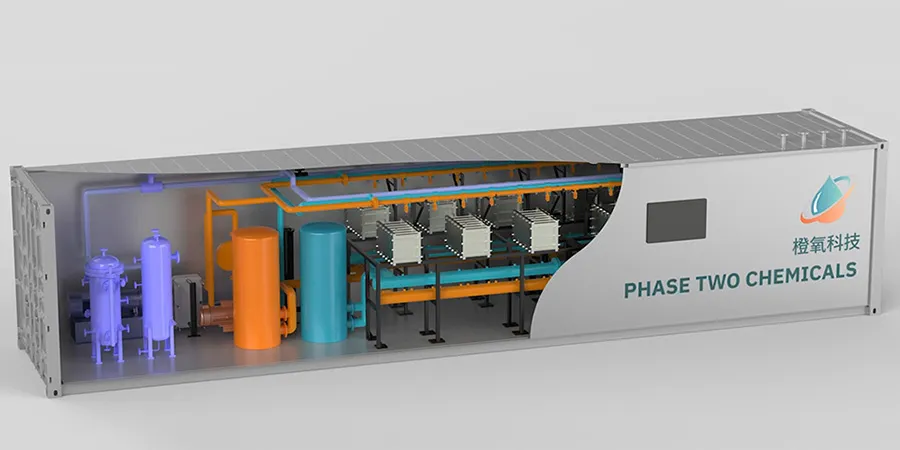

1.What are the dimensions and space requirements for hydrogen peroxide generation system?

The standard dimensions of the equipment are 11.4m*2.1m*2.5m, with a skid mounted structure that occupies an area of approximately 25 square meters. It needs to be installed indoors.

2.What are the input requirements for hydrogen peroxide generation system?

TPure water, electricity, oxygen, circulating cooling water, and alkaline solution.

3.What is the reaction principle of the equipment? What are the cathodic and anodic reactions? Is hydrogen gas generated? Why is it called alkaline hydrogen peroxide? What role does the alkali play? Why is it said that the alkali is not consumed?

Under alkaline conditions, oxygen and water are reduced to hydrogen peroxide on the cathode, while Na+ ions migrate from the anode to the cathode through an ion exchange membrane, forming sodium hydroxide. The cathodic reaction determines the fixed ratio at which sodium hydroxide and hydrogen peroxide are generated, with a theoretical mass fraction ratio of sodium hydroxide to hydrogen peroxide of 2.35. Sodium hydroxide is oxidized to oxygen and water on the anode. OH- is consumed on the anode and an equal amount of OH- is generated on the cathode. Therefore, sodium hydroxide is not consumed in the overall reaction system. Sodium hydroxide serves as a solvent carrier for hydrogen peroxide, which is produced at the cathode outlet, forming an advanced bleaching agent for pulp bleaching processes. Sodium hydroxide helps to improve conductivity and reduce energy consumption. The specific electrochemical reaction process is as follows:

Cathode reaction: O₂ + 2H₂O+ 2Na+ + 2e- → H₂O₂ + 2NaOH (alkaline hydrogen peroxide)

Anode reaction: 2NaOH → 1/2O₂ + H₂O +2Na+ + 2e-

Net reaction: 1/2O₂ + H₂O → H₂O₂

4.What are the outputs of the hydrogen peroxide generation system? What is the ratio of alkali to hydrogen peroxide in the bleaching solution? Is the ratio fixed?

The equipment outputs a mixed solution of alkali and hydrogen peroxide in a certain ratio. The cathode reaction determines the fixed ratio at which sodium hydroxide and hydrogen peroxide are generated, with a theoretical mass fraction ratio of sodium hydroxide to hydrogen peroxide of 2.35. The ratio is relatively fixed but can be adjusted within a certain range.

5.What is the adjustment range of the concentration of hydrogen peroxide?

The concentration can be adjusted between 0.5% and 5%, which is adjusted through the water replenishment amount and operating temperature of the equipment. If there are no special requirements, we generally supply hydrogen peroxide with a concentration of 3-3.5% to customers.

6.Will the hydrogen peroxide treatment system scale up?

7.What is the operating temperature for the operation of hydrogen peroxide generation equipment? Will extreme high or low temperatures in winter or summer affect the operation of the equipment or lead to freezing or increased energy consumption?

The hydrogen peroxide electrolytic generation system comes with a skid-mounted structure that needs to be installed indoors. The operating temperature of the system should be between 4-40 ℃, and the relative humidity should not exceed 60%. During equipment operation, the temperature of the electric stack and solution is 45 ℃. To ensure stable equipment operation, additional considerations need to be made for the material temperatures in the input and output of pipelines:

- The pipeline for 32% alkaline solution should ensure a solution temperature of at least 15 ℃. If not, heat and insulation are required.

- The water pipeline should ensure a temperature above 4 ℃. If not, heat and insulation are required.

- The alkaline hydrogen peroxide pipeline should ensure a temperature above 10 ℃. If not, heat and insulation are required. Specific requirements need to be determined based on the specific conditions of the project site.