- Moderate fiber characteristics: The moderate fiber length is beneficial for the strength and smoothness of the paper.

- Advantageous lignin content: Lignin helps in fiber bonding, enhances the stability and strength of the paper.

- High plasticity: Suitable for various papermaking processes, offering wide applicability.

- Regular paper: Used for producing general-purpose writing paper, printing paper, and other commonly used paper products.

- Packaging paper: Suitable for producing packaging paper with good strength and tear resistance.

- Sanitary paper: Can be used in the production of sanitary paper, and hygiene paper products.

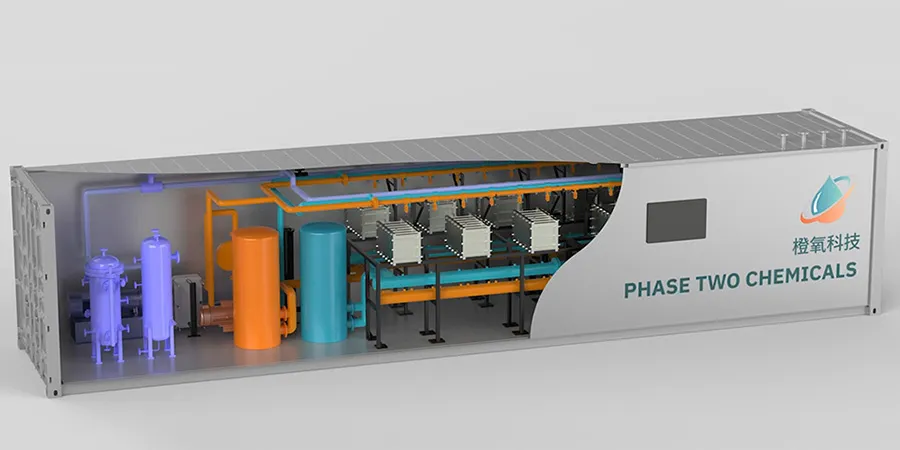

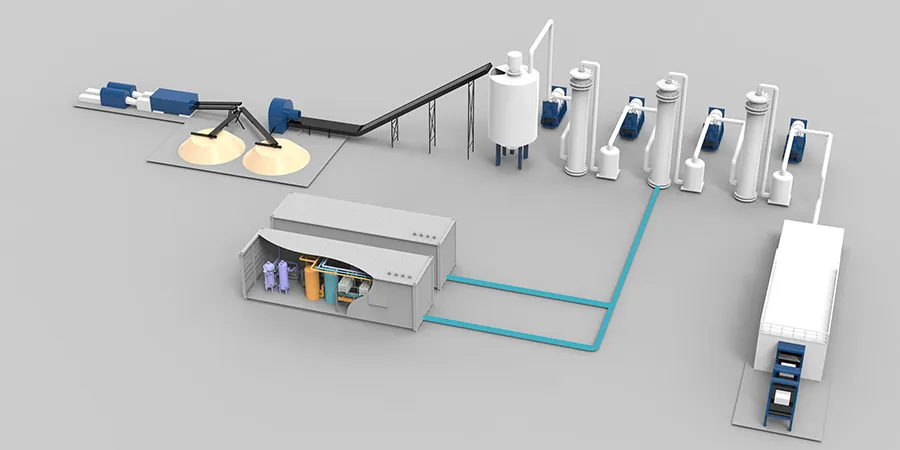

Traditional hydrogen peroxide processing methods are complex, uncontrollable, and difficult to transport. In some regions, they are strictly regulated, leading to high and uncontrollable costs for enterprises. Our independently developed hydrogen peroxide electrolysis system can effectively solve these problems:

- Our equipment can be installed anywhere, making it highly convenient.

- Our hydrogen peroxide production system uses a self-developed electrolysis system, making the manufacturing process more controllable and can be matched with our hydrogen peroxide manufacturing system based on demand.

- Our alkali hydrogen peroxide system can continuously and stably produce low-concentration hydrogen peroxide using only electricity, oxygen, and hydrogen, effectively resolving transportation and storage issues while meeting the environmental protection requirements.

- No storage risk: our hydrogen peroxide system supplies according to demand, without requiring additional hydrogen peroxide storage systems.

- Low-concentration hydrogen peroxide effectively preserves the pulp characteristics of poplar wood, making it easier to produce higher quality paper.

- We offer one-stop services for all your needs, from on-site equipment assembly, user training, remote monitoring, maintenance, to equipment upgrades.