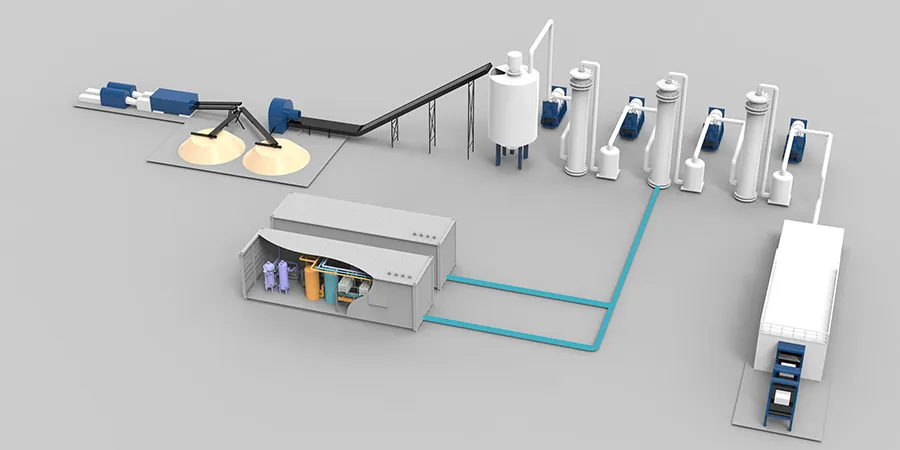

Phase Two Chemicals is committed to innovation and continuous improvement in the pulp and paper industry. In 2024, a leading pulp manufacturer in South China chose us to deliver a high-efficiency bleaching technology project. The goal objectives are to reduce bleaching costs, improve the efficiency of chemical bleaching solutions, and help the mill achieve lower operating costs and higher productivity.

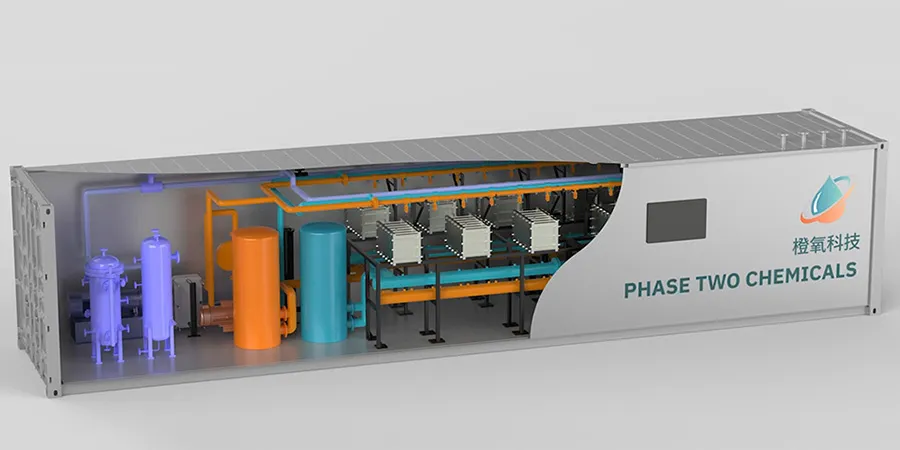

This project focuses on our independently developed low-concentration hydrogen peroxide system, with a production capacity of 1.5 tons/day (100% H₂O₂ equivalent). This system provides a more environmentally friendly and cost-effective option while ensuring stable and efficient bleaching performance.

The project began in mid-2024 and was completed by the end of the year, taking approximately four months. Following commissioning and trial operations, our high-efficiency chemical bleach system successfully met all design requirements, with both hydrogen peroxide concentration and output reaching targeted levels and qualities.

The pulp manufacturer produces over 100,000 tons of bleached chemical pulp annually, primarily bamboo mixed pulp. Before this project, the bleaching stage consumed about 1.9 tons/day of hydrogen peroxide (100% H₂O₂ equivalent). With our patented technology, the pulp mill has now replaced more than 75% of its purchased hydrogen peroxide with on-site production, ensuring a safer, more economical, and reliable supply.

Throughout the entire project, our team was responsible for design, procurement, logistics, and construction, and we delivered the project on schedule and in compliance with the contract standards. By maintaining close communication with the client, we provided timely adjustments and optimizations based on their operational needs. PTC will always be committed to ensuring the smooth execution of your long-term success.