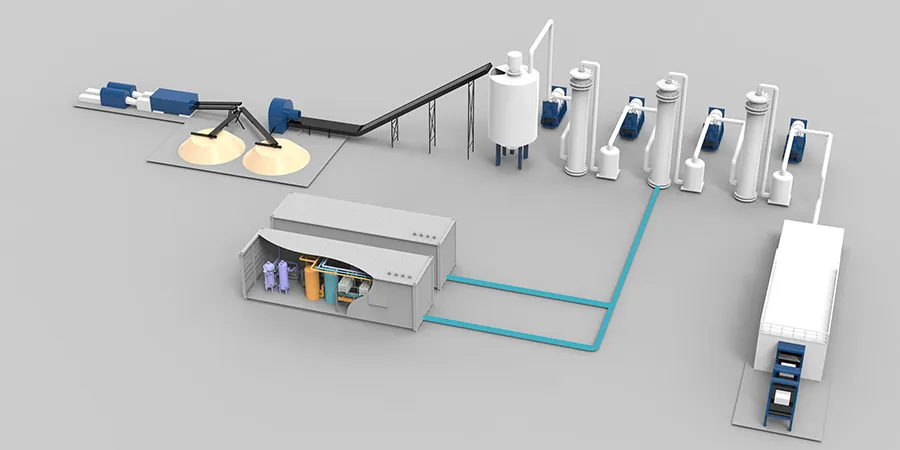

In the pulp and papermaking industries, a large amount of pine wood is used as the raw material. During the processing of pine wood, the use of low-concentration hydrogen peroxide is more conducive to maintaining the characteristics of pine wood and facilitating the production of high quality newsprint, packaging paper, and wood pulp boards for papermaking companies.

- Fiber length: pine wood comes with relatively long fibers, helping to improve the strength of the paper.

- Lignin content: moderate lignin content facilitates fiber bonding and enhances the stability of the paper.

- Natural resin: contributes to fiber adhesion and have a positive impact on paper quality.

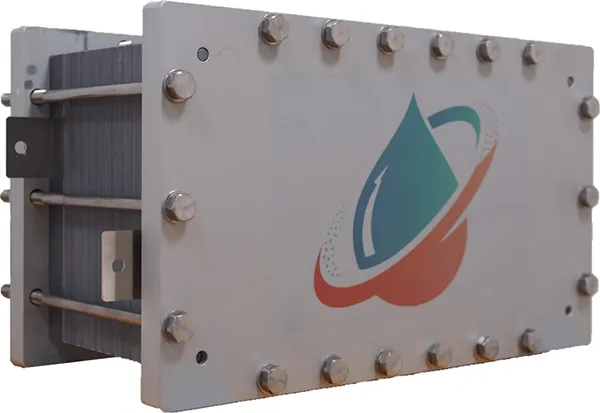

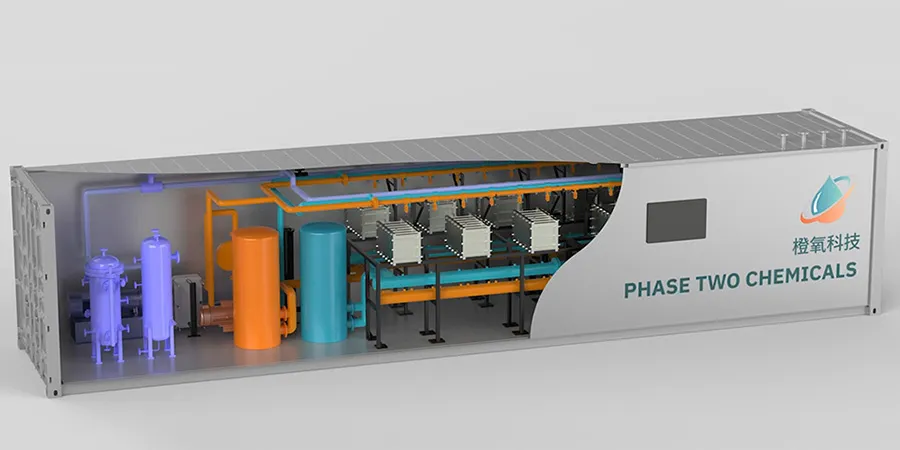

- Our electrolytic hydrogen peroxide generation system has no space and location restrictions.

- Our hydrogen peroxide production equipment makes the manufacturing process more controllable, solving the complexity and uncontrollable factors associated with traditional hydrogen peroxide production methods.

- Our hydrogen peroxide production system only requires electricity, oxygen, and hydrogen for continuous and stable supply, without the need for additional hydrogen peroxide storage systems.

- The hydrogen peroxide production process is environmentally friendly, with no pollutant emissions, meeting current environmental requirements for carbon reduction.

- The produced hydrogen peroxide features a concentration of no more than 6%, ensuring safety and effectively preserving the quality of pine wood fibers for the production of high-quality paper products.

- Controllable costs: cost is reduced by 20% to 40% for enterprise compared to traditional methods.