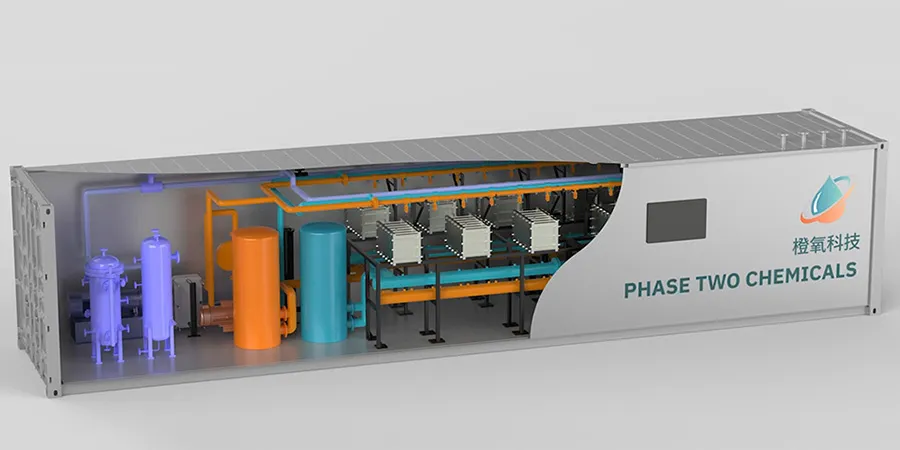

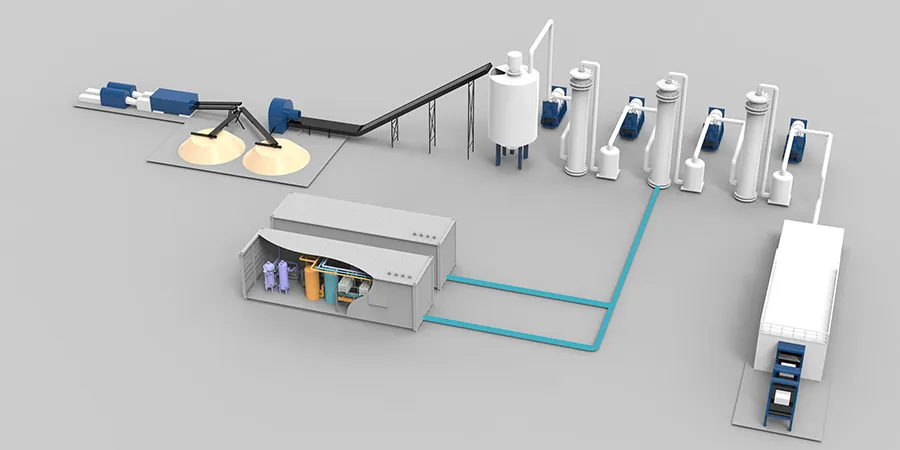

Phase Two Chemicals is changing the usage mode of hydrogen peroxide to provide controllable, cleaner, safer and more environmentally friendly bleaching production processes for pulp & papermaking enterprises, waste paper recycling companies, and others. This can reduce costs for businesses by 20% to 40% and provide a better alternative for the global paper industry!