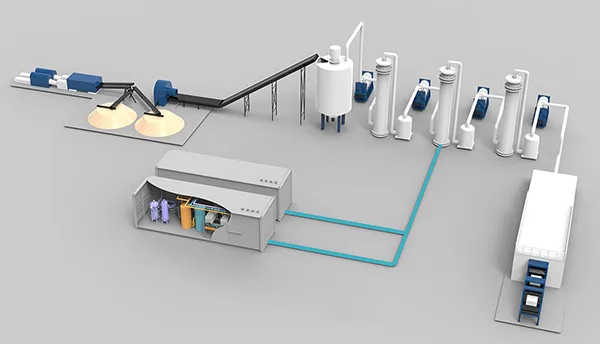

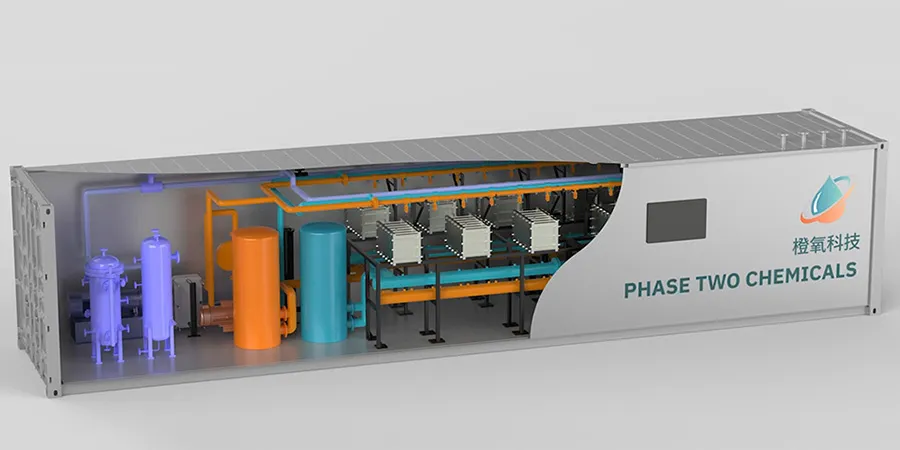

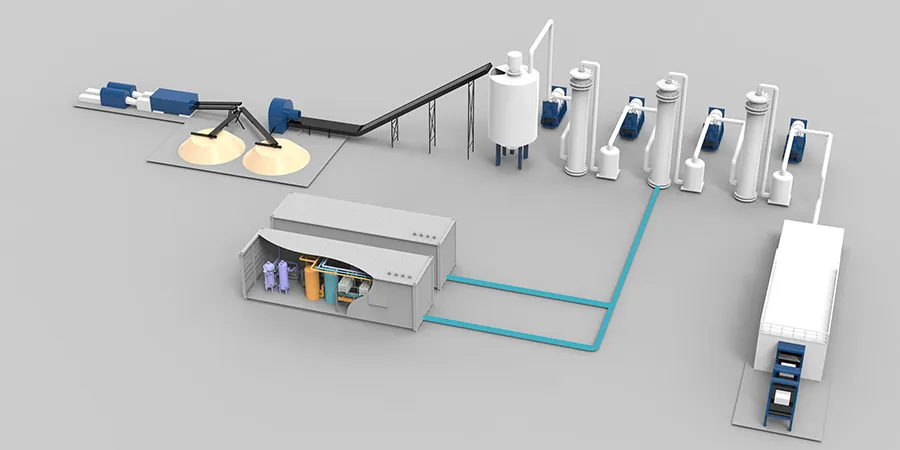

Our independently developed alkaline hydrogen peroxide electrolytic generation system provides a more environmentally friendly, efficient, and safe choice for BCTMP process.

The BCTMP (bleached chemical thermo-mechanical pulp) process combines the characteristics of thermo-mechanical pulp and chemical pulp. The wood is first mechanically processed and then treated with chemicals for bleaching to improve the quality of the pulp.

- Pollution concerns: Traditional chemical bleaching methods may result in pollution issues, and the bleaching effects may not be satisfactory.

- Excessive use of chemicals or improper control of bleaching time can damage the celluloses, affecting the quality of paper products for papermaking companies.

- Our hydrogen peroxide production system allows for continuous production of low-concentration hydrogen peroxide only using water, electricity, and oxygen

- On-site production of hydrogen peroxide solves the transportation and storage issues.

- The produced hydrogen peroxide is an environmentally friendly bleaching agent that does not cause pollution, reducing the investment costs for papermaking companies in environmental protection equipment.

- The low concentration hydrogen peroxide reduces the risk of damaging cellulose fibers.

- We offer a comprehensive leasing service for BCTMP process, providing customers with a one-stop bleaching solution with reduced investment costs, optimized production process, and peace of mind assurance.